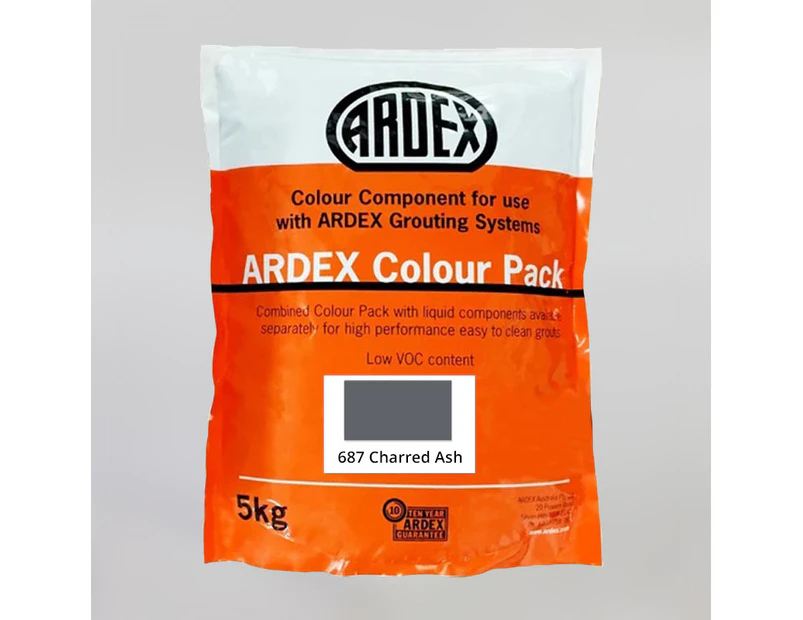

ARDEX EG15 Epoxy Grout 687 Charred Ash Colour Pack

ARDEX EG15 is a high performance epoxy grout designed for situations that require strict standards of hygiene, high chemical and physical resistance. ARDEX EG15 is exceptionally easy to clean up during application. It can be used in joints up to 15mm wide on walls and floors.

This EG15 Epoxy Grout 687 Charred Ash Colour Pack is only 1 part to a 3 part epoxy grout, you must also use a EG15 Epoxy Grout Liquid Part A & B pack which is parts 2 & 3.

All available colours are:

Travertine

Havana

Misty Grey

Magellan Grey

Slate Grey

Charred Ash

Black

White

Suitable for Internal and external use, Swimming and hydrotherapy pools.

For use with all ceramic tiles, porcelain and natural stone. Note: porous, moisture sensitive and textured tiles may require special application procedures, contact ARDEX Technical Services.

PREPARATION Ensure joints are clean and free from dust, excess adhesive

and bedding mortar. Do not grout until the adhesive has set

firmly. All ?spacers? must be removed from joints. Joints must

be dry before grouting and free from permanent dampness.

Prior to grouting, it is advisable to check ease of cleaning with

tiles that have a textured or matt surface.

MIXING RATIO ARDEX EG15 should be mixed to the ratios below in

parts per volume:

Part A Compound 2 parts/1L

Part B Hardener 1 part/500mL

Part C Colour Pack 5-7 parts/5kg

MIXING Only mix enough material that can be used within 30 minutes.

Shake well before opening plastic bottles.

- Transfer the measured amount of compound (Part A) to a suitable sized mixing container and add the hardener (Part B).

- Mix the two components using a low speed mechanical stirrer (e.g. electric drill) until a uniform mixture is obtained. Smaller quantities can be mixed by hand in the manner

described. - Add ARDEX Colour Pack (Part C filler) in incremental amounts until the desired consistency and a uniform colour is obtained.

Notes on mixing:

A. Filler addition can be adjusted to accommodate site conditions (e.g. ambient temperatures, joint width).

B. Coverage will vary dependant on the amount of filler added. Reducing filler decreases coverage, allows more slump and makes clean up more difficult. For wider joints, more filler may be necessary to obtain a firmer, non-slump consistency.

C. To extend the pot life, spread the mix onto a non-absorbent surface (e.g. plastic sheet) at a thickness not exceeding 15mm and begin application.

D. To optimise the workability, incorporate less ARDEX Colour Pack Part C filler at low temperatures into the mix.

APPLICATION Apply the mixed grout using a spatula, gauging trowel or caulking gun. Compact the grout firmly into the joints ensuring they are completely filled, minimising the amount left on the tile surface. Remove excess grout from the tile surface and begin cleaning.

Optimum pot life, coverage and workability are achievable when ARDEX EG15 is used at temperatures between 20-25?C.

The components can be warmed or cooled to achieve optimal results depending on temperature and site conditions. Do not apply in temperatures below 10?C or above 30?C. Low temperatures will retard curing and high temperatures will dramatically shorten the pot life. The pot life of the mixed mortar is approximately 45 minutes at 23?C and 50% relative humidity, when approximately 200mL are mixed. Warmer temperatures and larger mixes will reduce the pot life, only mix sufficient material that can be used within 30 minutes.

Call GroutPro on 1800 822 459 for professional installation.